Testing and automation

We have 15 years of experience in the development of industrial testers. Now we mainly deal with testers for checking quality of printed circuit boards and testers for production lines. But thanks to our knowledge in both high current and low current, we can manufacture various custom-made devices that are not easily found on the market.

Testers are the ideal solution, whether you are dealing with ever-increasing demands for quality control or a lack of qualified employees.

Reliability

Testing with functional testers is fast and reliable, enabling quick and accurate product testing. This will save you a lot of time, and you can focus on other projects.

Quality verification

Another advantage of using functional testers is ensuring product quality. The function tester will reveal which one is working properly and which one is faulty.

Cost savings

Functional testers enable accurate and thorough testing of products before further processing. You will discover which circuit board to send for repair and not use it in the next step.

Testing results

Checking one piece of PCB takes a few minutes and any worker can operate the tester after training. The test results are automatically saved in the log at any time.

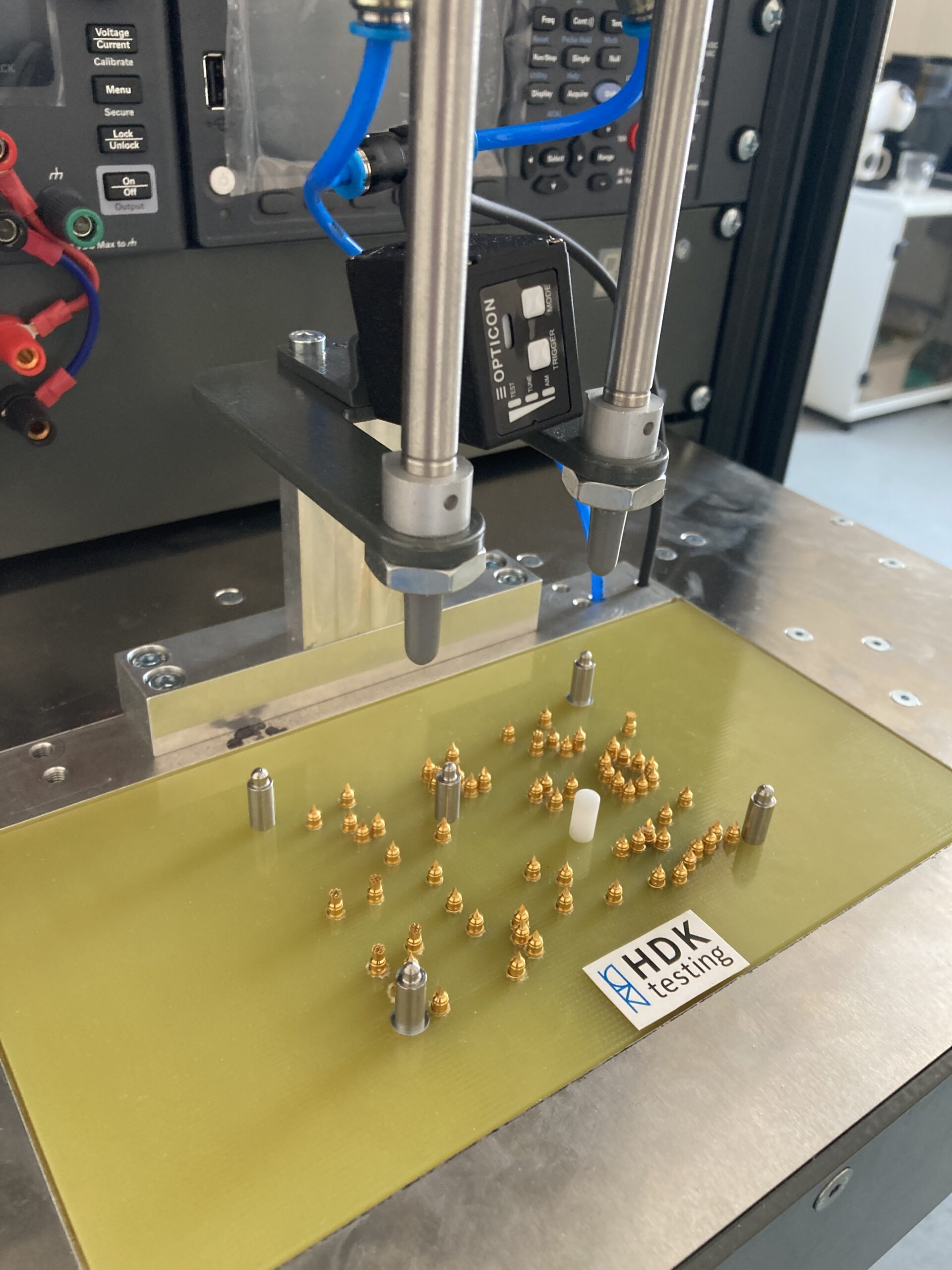

Modularity

Do you need to test series of different types of PCBs on one tower? Then replace the adapter for the specific kind of PCB and run the appropriate tests 📑.

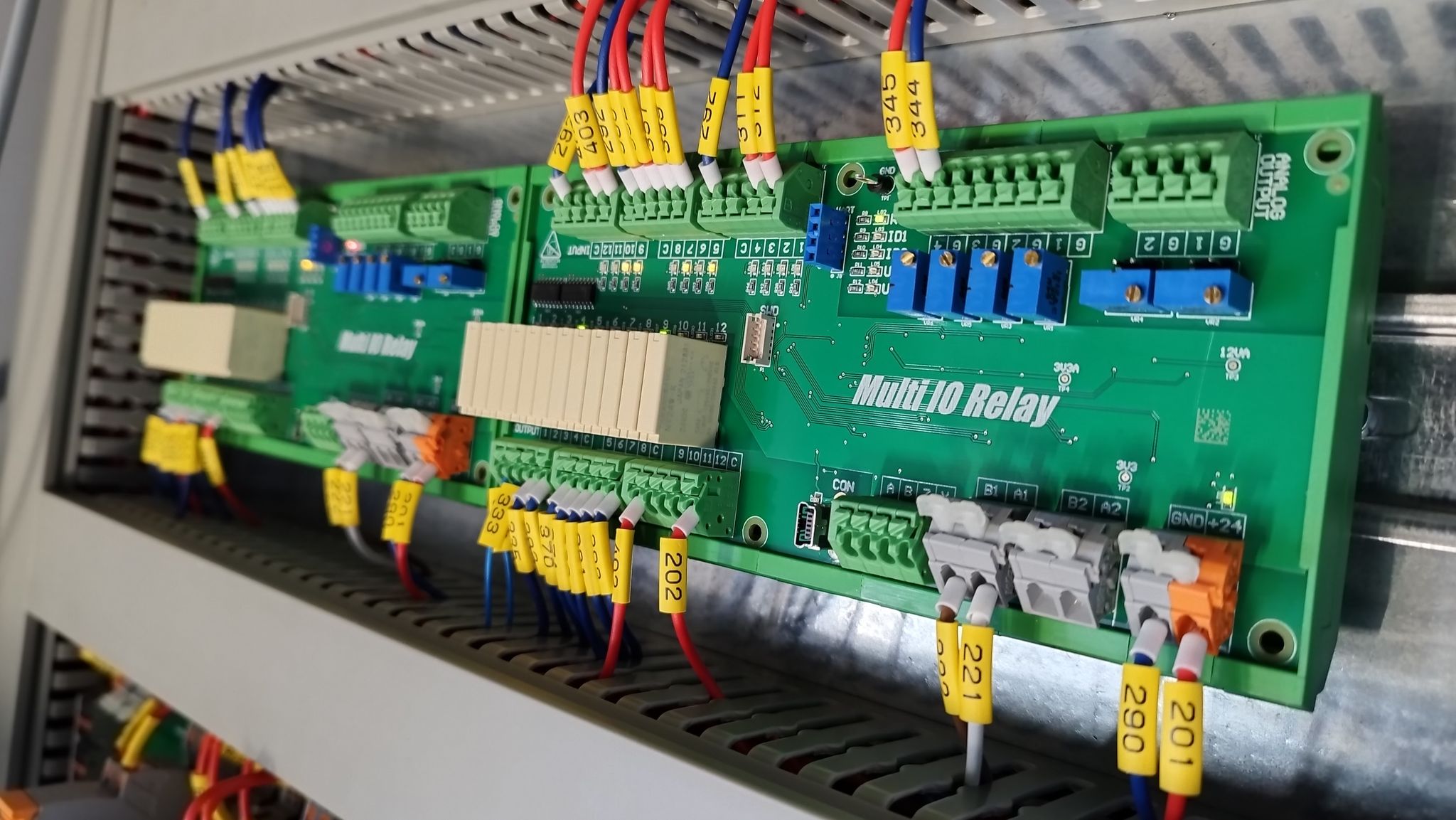

We use printed circuit boards developed by us for testing. We select the most suitable for testing, and with their help, we check that the product (or its electronic parts) works perfectly.